-

Design for Manufacturability (DFM) in Photo Chemical Machining: A Guide for Engineers and Designers

In the world of precision metal components, achieving intricate designs with tight tolerances can be a challenge. Photo Chemical Machining (PCM) offers a…

-

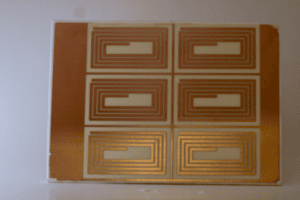

Why Use Photo Etching for Power Electronic Devices

The umbrella term power electronics refers to a range of semiconductor devices that are used to manage and manipulate the voltage,…

-

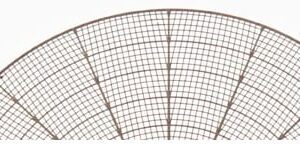

Why OEMs Rely on Photo Etching for Key Applications

From semiconductors to fuel cells to filtration to medical devices –and many more– major OEMs, names you will instantly recognize,…

-

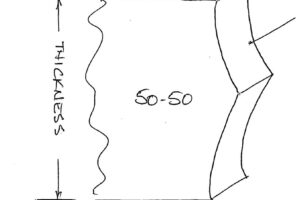

What to Know about Photo Etched Sidewalls

Different metal cutting processes produce different effects at the cut line. Stamping and punching can leave a deformation and a…

-

Sheet Size and Tolerances: Cost Drivers in Photo Etching

Three Leading Factors The three biggest variables affecting the cost of photo etching are metal thickness, sheet size and tolerances. Metal…

-

5 reasons OEMs should choose a value-added supplier for Photo Etching

Here are five reasons why you should consider a value-added photo etching supplier for your OEM. It’s surprising to get inquiries…

-

Photo Etching: 2023’s Top Ten FAQs

Over the course of a year, we talk with a lot of people–most of whom have questions. We’ve compiled the…

-

How Photo Etching is a Capable Alternative to Other Metal Fabricating Processes

Photo Etching vs. “the Others” Photochemical machining is the industry’s preferred moniker for this metal fabrication process. It is also readily…

-

How Does Photo Etching Work and What Are Some Applications for It?

Photo etching has evolved from a niche process to one that serves a wide variety of industries with precision metal…

-

Getting a conceptual grasp of photo etching

When it comes to understanding how photo etching works, there seems to be a conceptual gap – many of the…