5 Key Problems of Photo Chemical Machining

Comments Off on 5 Key Problems of Photo Chemical MachiningThe three biggest problems with photochemical machining are that it is not well known; it is little understood; and it has too many names. Here’s a major case of multiple identity disorder: photo chemical machining, PCM, photo chemical etching, photo etching, chemical etching and chemical machining all refer to the same process.

There are three additional, similar sounding processes that are NOT photo etching.

- Electro chemical etching (sometimes called electrolytic etching) is a process used for part marking on metal parts.

- The MetalPhoto process utilizes pre-treated aluminum panels to create nameplates and identification products.

- Chemical milling is a process used to modify parts by selectively removing metal from specific areas. Chemical milling is often used on airframe components to reduce weight. In this context, chemical milling may be subject to Nadcap checklist 7108/5. Nadcap (formerly NADCAP, the National Aerospace and Defense Contractors Accreditation Program) is a global cooperative accreditation program for aerospace engineering, defense and related industries. Nadcap covers a range of special processes with uniform standards.

Photochemical etching is not subject to Nadcap because the etching process does not alter the properties of the material.

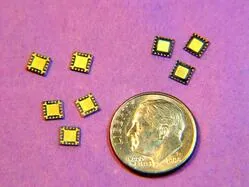

Another problem with photochemical machining is that it is a relatively rare process. There are only about 100 PCM shops in the country and barely a few hundred globally. Compare that to about 2,000 metal stamping shops just in the US. Photochemical etching is often a better solution to fabricating flat metal parts, but too few people are familiar with the process.

We also have to overcome the misperception about etching and the environment. Today, all-aqueous chemistries are used. PCM is closely monitored by environmental protection departments in every state where there are PCM shops. We take environmental responsibility very seriously. We have state of the art water treatment facilities. Our process waste water is cleaner than the municipal water supply. We actually have to clean the city water before we can use it in the etching process.

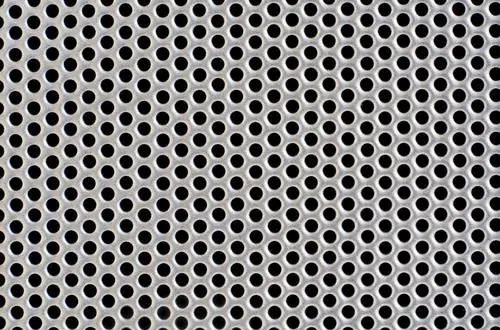

Photo etching is a process that involves a considerable suite of specialized facilities and equipment. It’s surprising how often we receive inquiries from people who “want to buy a photo etching machine.” It’s not a photocopier.

Photo etching is a metal fabricating process that fits in a spectrum that includes metal stamping, CNC punching, laser, plasma and water-jet cutting, and wire EDM. The end result of all of these processes is flat metal parts. Stamping and punching are processes that require hard metal tooling to cut parts from sheets of metal. Laser, plasma and water jet use narrow beams of focused energy. In the case of the laser, the energy comes from colimated light, and the water jet uses a pressurized abrasive slurry. Plasma uses a beam of highly energized gas. Wire EDM uses a wire electrode to burn the parts out of metal.

Stamping and punching create mechanical stresses and burrs on the metal. Laser, plasma and EDM generate thermal stresses which may alter the characteristics of the metal.

Among the advantages of etching is that etched parts do not acquire any thermal or mechanical stresses during fabrication. The unwanted metal is dissolved by the etchant and rinsed away. We think of it as “stress free machining.”

Thousands of companies in dozens of industries rely on etched metal components in their products.

For more information:

Design Considerations

for Photo Etching

Or: