Enabling High-Performance, Mission-Critical Designs Without Compromise

Conard is AS9100D /ISO9001 registered

- National Quality Associates Certificate 11619

- ITAR Registration Number M27542

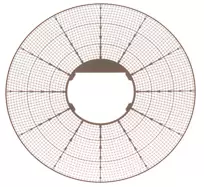

Photochemical machining is used to produce metal components for many types of aerospace applications from airframe stiffeners and heat sinks to satellite batteries.

Aerospace and defense applications demand uncompromising precision, reliability, and material performance. From avionics thermal management to jet engine assemblies and aircraft fuel control systems, component tolerances are tight, geometries are complex, and failure is not an option. Photo chemical machining (PCM), also known as photochemical etching. has become a trusted manufacturing process for producing high-precision metal components used in aerospace and defense systems where accuracy, repeatability, and material integrity are critical.

Aerospace customers include:

Applications of Photochemical Machining for Defense & Aerospace

Unlike mechanical machining or thermal cutting methods, photo chemical machining produces burr-free, stress-free metal parts with intricate features that support advanced aerospace designs. This makes PCM an ideal solution for lightweight, high-reliability components used in both commercial and military aerospace platforms.

PCB Heatsinks for Aerospace Electronics

Modern avionics systems generate significant heat while operating in environments with limited airflow and extreme temperature variation. PCB heatsinks and thermal management components produced via photo chemical machining help maintain system reliability in flight-critical electronics.

Because PCM does not introduce mechanical stress or thermal distortion, etched heatsinks maintain flatness and conductivity; both are essential for avionics reliability. This is especially valuable in radar systems, flight controls, navigation electronics, and defense communication platforms.

Precision Components for Aircraft Fuel Control Systems

Aircraft fuel control systems require absolute dimensional accuracy and repeatability to ensure proper flow, metering, and system safety. Components such as fuel control plates, screens, shims, and metering elements often feature fine slots, apertures, or flow paths that are difficult or costly to produce with conventional machining.

PCM is particularly effective for thin-metal fuel system components where edge quality and dimensional accuracy directly impact performance and safety.

Braze Foil Preforms for Jet Engine Assemblies

One of the most critical aerospace applications for photo chemical machining is the production of braze foil preforms used in jet engine and turbine assemblies. These preforms must deliver precise alloy placement during brazing to ensure joint integrity under extreme thermal and mechanical loads.

Photo chemical machining allows aerospace manufacturers to tailor braze foil preforms for specific engine components, supporting higher efficiency, longer service life, and improved reliability in turbine engines and propulsion systems.

Materials Commonly Used in Aerospace PCM Applications

Photo chemical machining supports a wide range of aerospace-approved metals, including:

- Stainless steels (300 & 400 series)

- Nickel alloys (Inconel®, Hastelloy®)

- Copper and copper alloys

- Aluminum alloys

- Kovar® and specialty expansion-controlled materials

This material flexibility allows engineers to optimize components for weight, strength, corrosion resistance, and thermal performance without changing fabrication methods.

Expertise in photo etching aluminum led to the founding of the The Conard Corporation in 1965.

Conard’s ability to etch aluminum up to .080″ thick continues to find new applications in many industries.

Photo chemical machining is exempt from Nadcap checklist 7108/5 because the process does not alter any of the properties of the metal. Read more about this in our Blog: What is the difference between photoetching and chemical milling?

Precision Aerospace Manufacturing by Conard Corp.

When performance, reliability, and precision define success, photo chemical machining delivers aerospace-ready metal components without compromise. From avionics heatsinks to fuel control systems and jet engine braze foils, PCM enables designs that meet the highest aerospace and defense standards: efficiently, repeatably, and with exceptional quality.

Ready to bring your next aerospace component to life? Let’s engineer it together.