Precision Metal Components for Advanced Semiconductor Manufacturing

Photo chemical machining (PCM) (also known as photochemical etching) has become a critical fabrication technology for producing ultra-precise, burr-free metal components used throughout the semiconductor and microelectronics packaging supply chain.As semiconductor devices continue to scale in complexity, performance, and miniaturization, manufacturers of microelectronics packaging and assembly systems face unprecedented demands for precision, reliability, and material performance.

From lead frames and heat spreaders to EMI/RFI shielding, micro-springs, and fine-feature interconnect components, PCM enables function-first designs that conventional metal fabrication processes struggle to achieve.

Applications of Photo Chemical Machining in Semiconductors & Microelectronics Packaging

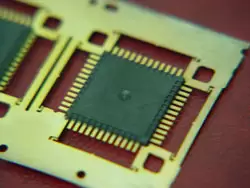

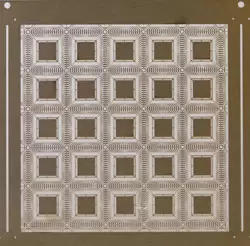

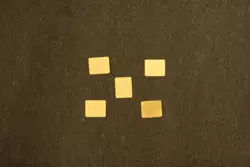

Lead Frames for IC Packaging

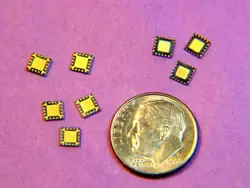

These devices can range from simple DIP to very intricate and delicate high density QFN. They are often made from a high performance copper alloy such as C194. Lead frames are foundational in semiconductor packaging, especially in QFN, QFP, and power device assemblies.

A group of nickel-iron-cobalt alloys, known generally as “glass-to-metal sealing” alloys—of which Kovar may be the best known brand name, are also popular choices for both leadframes and “lids,” the closure devices for hermetically sealed packages. Lids may be flat or stepped and are typically produced without tabs. Again, precision metal etching is the best way to produce parts that are flat and burr-free.

Heat Spreaders & Thermal Management Components

Thermal control is critical in high-density ICs, power semiconductors, and advanced packaging architectures. Because PCM preserves flatness and material properties, etched components maintain optimal thermal conductivity, which is essential for long-term device reliability.

EMI / RFI Shielding for Microelectronics

Electromagnetic interference is a persistent challenge in semiconductor packaging and system-level integration. Photo chemical machining enables the production of thin, intricate EMI/RFI shielding components and is ideal for shielding solutions for chip packages, modules, and board-level assemblies without the deformation risks associated with stamping or forming.

Micro-Springs, Contacts & Interconnect Components

As devices shrink, mechanical compliance becomes increasingly important. Micro-springs and interconnects parts often require complex geometries in thin metals that must flex reliably over millions of cycles, something PCM supports through stress-free fabrication.

Semiconductor Test & Handling Components

Semiconductor testing and handling systems rely on precision metal parts to ensure alignment, conductivity, and durability. The ability to rapidly modify designs without new tooling makes PCM especially valuable during test system development and qualification.

Materials Commonly Used in PCM for Microelectronics

Photo chemical machining supports a wide range of metals used in semiconductor manufacturing, including:

- Copper and copper alloys

- Stainless steels

- Nickel and nickel alloys

- Alloy 42 and Kovar®

- Molybdenum and specialty metals

This versatility allows engineers to optimize electrical, thermal, and mechanical performance without compromising manufacturability.

High-Precision Microelectronics by Conard Corp.

In semiconductor and microelectronics packaging, precision is non-negotiable. Photo chemical machining delivers the design freedom, reliability, and scalability engineers need to meet today’s challenges. Whether you’re developing next-generation IC packages or optimizing high-volume production components, PCM provides a competitive advantage from concept through commercialization.

Contact us for more information to explore how photo chemical machining can support your semiconductor manufacturing goals.