What are the Problems of Cutting and Photo Etching Aluminum?

Comments Off on What are the Problems of Cutting and Photo Etching Aluminum?One of the lightest metals, aluminum, is one of the more challenging alloys to to process. This post will compare laser and plasma cutting with photo etching with regard to cutting aluminum.

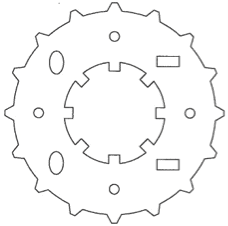

The biggest problem with laser and plasma cutting is heat. Aluminum melts at about 1200 degrees F. The plasma stream is about 25,000 degrees. By definition, laser cutting is a process of melting the material in its path, so the work piece will be subjected to high temperatures. The thermal impact of these processes can produce a recast or slag layer, known as the Heat Affected Zone (HAZ). This thermal exposure can alter the properties of the metal, which is generally undesirable. By comparison, the photo etching process rarely gets warmer than 150 degrees, about the same as your dishwasher.

Dimensional accuracy is another area where there are meaningful differences between laser, plasma, and photo etching.

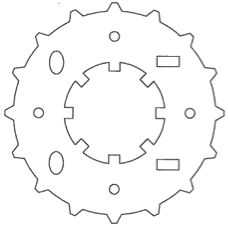

On plasma cutters, the beam width is determined by the nozzle size, with a ratio of 1.5 to 2X nozzle diameter to beam width. It is possible to put a .001 nozzle on a plasma cutter to produce a .002 beam, but you can’t push very much power through that aperture. Dimensional accuracy of plasma cutters runs about +/-.015-.020″.

On laser cutters, the beam width is determined primarily by the optics. For metal cutting machines, typical beam widths of .006-.016″. (Laser marking machines can have much smaller beams.) Laser cutters can achieve +/-.005″ dimensional accuracy. Two additional issues with laser cutting aluminum are optical reflectivity (aluminum is shiny) and thermal conductivity (the metal dissipates the heat the laser is trying to generate.)

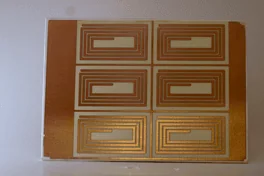

In photo etching, dimensional tolerances are +/-15% of material thickness. For metals that are .032″ or less in thickness, photo etching will easily produce tolerances that are tighter than +/-.005″.

The etching challenge with aluminum is that is it a very active and reactive metal. It oxidizes readily and actually becomes fuel for the etching reaction. Another problem is that aluminum will etch in both acids and bases. The solution used to dissolve the acid-resistant photo resist is a base. In the process design for etching aluminum, allowance has to be made for the slight but inevitable etching during the stripping process.

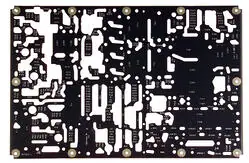

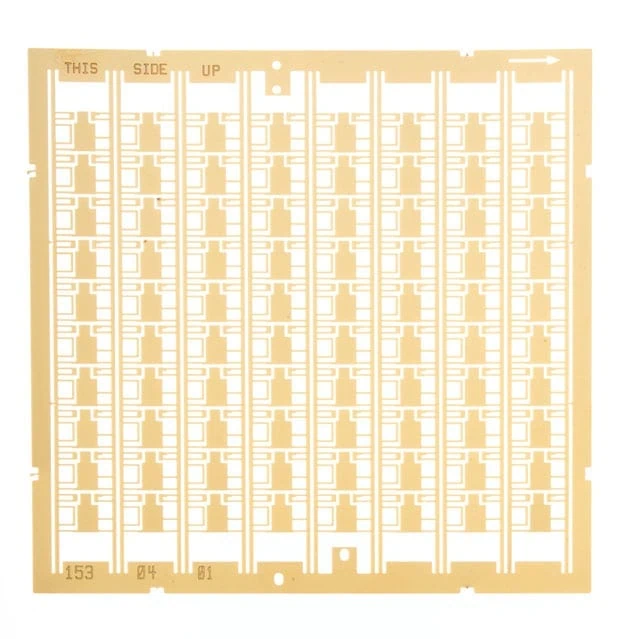

Photo etching has proven to be a versatile and cost effective method of fabricating thin-gauge metal parts in many alloys. The vast majority of metals can be successfully photo etched using ferric-chloride etchants, which are among the easiest, safest and most economical to use. However, ferric chloride does not produce the best results on aluminum.

Etching aluminum is the foundation of Conards business. In the early 1960s, Dick Huttinger, a metallurgist for Pratt and Whitney, was trying to find a better way to finish the surfaces of forged aluminum propeller hubs. At that time, CNC machining was neither sufficiently sophisticated nor cost effective for the task. Huttinger believed that it could be done chemically and developed the methodology that we continue to use to this day.

Our General Manager, Art Long, has worked in this industry for more than 30 years and is well familiar with the challenges of etching aluminum. The biggest problem is edge consistency, sometimes the edge would look smooth and other times it would appear very rough. It was difficult to control the quality of the etchant from one bath to the next and from one alloy to the next, said Long. When I joined Conard in 2003, I noticed that the aluminum etching capabilities were head and shoulders above the previous companies I had worked for. The product had consistently smooth sidewalls and was precise in a wide range of different aluminum alloys and thickness.

For more information, contact us at 860-659-0591 or: