The Benefits of Photo Chemical Machining for Metal Filtration Devices

Metal filtration devices play a crucial role in industries ranging from aerospace and automotive to medical, chemical processing, and energy production. These components often require intricate, high-precision perforations and complex geometries to meet functional and performance demands. For manufacturers and design engineers seeking both precision and production efficiency, photo chemical machining (PCM) presents a compelling fabrication method. PCM offers a range of benefits that make it especially well-suited to producing metal filtration devices, including design flexibility, tight tolerances, cost-effectiveness, and superior edge quality.

1. Unmatched Design Flexibility

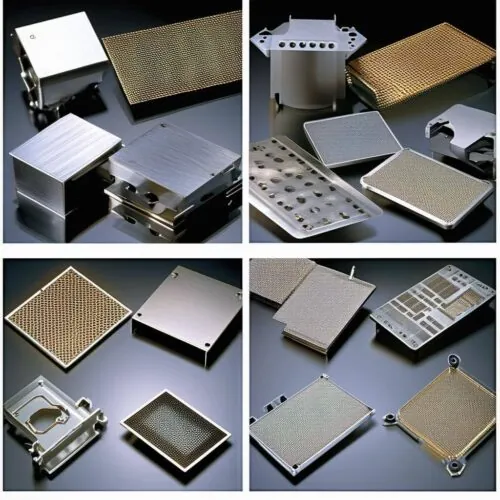

One of the primary advantages of photo chemical machining for filtration components is its ability to create highly intricate and complex patterns in thin metal sheets without the constraints imposed by mechanical tooling. Filters often require thousands—or even millions—of uniform openings, some in custom or non-standard shapes, aligned precisely for fluid or gas flow control.

PCM uses a photomask and chemical etchants to dissolve unwanted metal areas, allowing for:

-

Free-form geometries (slots, grids, hexagonal, elliptical, or irregular apertures)

-

Complex aperture patterns that would be difficult or impossible with stamping or drilling

-

Micro-scale features with consistent repeatability

Because PCM is a mask-based process, design changes can be implemented quickly and inexpensively by simply modifying the phototool—without the need for costly retooling or mechanical adjustments. This is particularly beneficial during prototyping or low-to-medium volume production runs, where agility and customization are key.

2. Tight Tolerances and Dimensional Accuracy

High-performance filtration systems depend on predictable and uniform aperture sizes to ensure consistent flow rates, pressure drops, and separation performance. PCM is capable of achieving fine feature resolution—often in the range of ±0.025 mm (±0.001 inch) or better—while maintaining flatness and structural integrity of the metal.

Unlike traditional punching or laser processes, PCM does not introduce mechanical or thermal stress to the material. There is no tool pressure, heat-affected zone, or deformation around the cut areas, which means:

-

Apertures maintain their shape and spacing precisely

-

Parts remain flat and free from burrs or warping

-

Thin metals as light as 0.0005 inches can be accurately machined

Such precision is critical in medical, fuel cell, or aerospace applications where even slight deviations in pore size can affect system performance or safety.

3. Burr-Free Edges and Superior Surface Quality

Filtration components, especially those used in sensitive applications like fluid or gas purification, demand clean and smooth aperture edges to prevent particle retention, bacterial buildup, or flow disruption. Mechanical punching or laser cutting can leave burrs, sharp edges, or recast layers that compromise performance and require secondary finishing.

In contrast, photo chemical machining is a non-contact, non-thermal process:

-

No mechanical burrs are formed

-

No edge deformation or micro-cracks

-

No heat-affected zone or metallurgical changes

This results in high-quality surface finishes that meet or exceed industry standards without the need for secondary deburring or polishing operations, reducing overall processing time and cost.

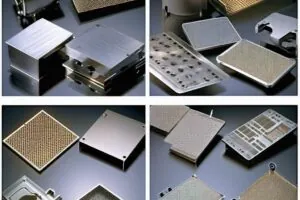

4. Material Versatility

Photo chemical machining supports a wide range of metals used in filter applications, including stainless steel, nickel alloys, copper, brass, aluminum, and titanium. The process is especially well-suited to thin metals (typically from 0.0005 to 0.060 inches), and its chemical nature means that hard or exotic materials are no more difficult to machine than softer ones.

This versatility enables PCM to support a diverse set of filtration solutions, including:

-

EMI/RFI shielding screens

-

Mesh or grid-type fuel injector filters

-

Blood filtration membranes

-

Chemical processing sieves and diffusers

Additionally, multiple metals can be processed in parallel using similar tooling, which is useful for multi-material filter assemblies or hybrid system designs.

5. Cost-Effectiveness for Prototyping and Production

Unlike stamping or EDM, PCM does not require expensive hard tooling. The phototool—a film used to expose the metal—is inexpensive and fast to produce, often in a matter of hours. This makes photo chemical machining ideal for:

-

Rapid prototyping with production-quality results

-

Small-to-medium production runs

-

Low product development cost and faster iteration cycles

Even in high-volume applications, PCM remains cost-competitive due to its ability to etch multiple parts per sheet simultaneously (nesting), and its reduced need for post-processing.

6. Scalability and Repeatability

Once a design is finalized, PCM offers excellent repeatability and scalability. Parts are consistently replicated with high precision and virtually no variation across large production batches. Process control, automation, and mask-based exposure ensure that each part conforms to exacting specifications, reducing waste and increasing yield.

Conclusion

For engineers and designers of metal filtration devices, photo chemical machining offers a compelling combination of precision, design freedom, material compatibility, and cost control. Whether you’re developing micro-perforated fuel filters, surgical screens, or high-flow industrial sieves, PCM provides the capability to fabricate complex features reliably, burr-free, and to exact specifications—all while maintaining the flexibility to adapt to evolving designs or production demands.

In a world increasingly dependent on clean, efficient, and precise filtration systems, photo chemical machining stands out as an advanced manufacturing solution that enables innovation without compromising quality.

For More Information:

Contact Page Form

"*" indicates required fields